Application of GPS / BeiDou timing and positioning function in distribution network automation

Release time:2020-04-07 11:17:55

With the acceleration of the construction of the ubiquitous electric power Internet of Things, the traditional manual inspection has the problems of high labor cost, low efficiency, and difficult operation, etc., and it has continuously led to the reform of the old working methods.

Industry requirement

Failure of power equipment requires manpower to find the failure point, which is slow and time-consuming;

Inaccurate positioning of power line fault locations;

It is impossible to accurately obtain the time when the power line failure occurred.

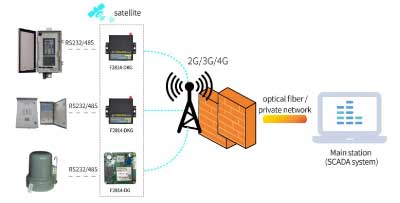

Four-Faith wireless communication module combines GPS / BeiDou positioning function. The solution uses electric power dedicated wireless communication modules F2814-DKG and F2814-DG to connect field devices and the master station system. The built-in GPS / BeiDou module solves the problem that the wireless communication module cannot have both Data transmission and satellite timing and positioning functions; ensures that the master station system can accurately obtain the location of the terminal on the site and the time of the fault. The time of the fault is accurate to the millisecond level, which facilitates maintenance personnel to rush to the site quickly. This is of great positive significance for terminal fault repair and regular maintenance.

Solution Advantages

1、GPS / BeiDou timing and positioning function can obtain time information from satellite signals spontaneously without manual adjustment. The time is accurate to the millisecond level, and the maintenance work can be more accurate and efficient.

2、Embedded design and small size meet the structural requirements of power distribution automation equipment, and is easy to connect with customer equipment.

3、Built-in standard TCP / UDP

protocol, support transparent data transmission; support dual data center backup transmission and multiple data center synchronous transmission (5 data centers) to facilitate management departments to obtain data and increase supervision.

4、The terminal can be connected to the equipment remote management platform to centrally monitor, configure, upgrade, diagnose, and maintain equipment scattered in various areas, which greatly reduces the maintenance costs of operators, integrators, and equipment providers, and improves management efficiency.

Overhead Line Fault In

Overhead Line Fault In Wall-Mounted Cable Lin

Wall-Mounted Cable Lin Protocol Converter Gat

Protocol Converter Gat Industrial Cellular Ro

Industrial Cellular Ro HV Power Line Security

HV Power Line Security F-ICB100 380V smart ci

F-ICB100 380V smart ci Multifunction Power Me

Multifunction Power Me F-FTU200 Auto Circuit

F-FTU200 Auto Circuit  LoRa Module & Gateway

LoRa Module & Gateway Network Camera

Network Camera Serial to Cellular

Serial to Cellular  5G Router

5G Router

Chinese

Chinese

Download

Download Demo

Demo Wiki

Wiki FAQ

FAQ themes

themes